Our Services

About Model

Architectural Models

-

Architectural model is a physical or digital representation of a building or structure. It can be used to communicate the design intent of the building to clients, stakeholders, and construction teams.

-

There are different types of architectural models, including:

- Conceptual models: These are usually small- scale physical models or 3D computer models that are used to explore design ideas and communicate the overall concept of the building.

- Design development models: These models are more detailed and are often used to communicate the design intent to clients and other stakeholders. They may include materials, textures, and lighting to give a more realistic representation of the building.

- Construction models: These are highly detailed models that are used by construction teams to plan and coordinate the construction process. They may include information about structural elements, mechanical systems, and other details important for construction.

-

Architectural models can be created using a variety of materials, including wood, plastic, foam, and 3D printed materials. They can also be created using computer software, such as CAD (Computer-aided design) and BIM (Building information modeling) software.

-

Architectural models can be an important tool in the design, construction, and marketing of buildings and structures. They allow designers, clients, and other stakeholders to visualize the building in a more tangible way and can help to identify and resolve potential issues before construction begins.

About Model

Industrial Models

-

Industrial model making is the process of creating physical models of products, buildings, and other objects to be used for design, testing, and marketing purposes. These models are typically made using a variety of materials, including plastics, metals, woods, and composites.

-

The process of industrial model making begins with a design or concept, which is then translated into a digital 3D model using computer-aided design (CAD) software. From there, the 3D model is used to create a physical prototype using various manufacturing techniques, such as 3D printing, CNC machining, or traditional handcrafting.

-

Industrial model making is an essential part of the product development process, allowing designers and engineers to test and refine their designs before committing to full-scale production. Models can be used to evaluate the functionality, aesthetics, and ergonomics of a product, as well as to identify potential design flaws and areas for improvement.

-

In addition to product design, industrial model making is also used in architecture and urban planning to create physical representations of buildings and cityscapes. These models can be used to evaluate the visual impact of new construction projects or to simulate the effects of natural disasters and other events.

-

Overall, industrial model making is a highly specialized field that requires a combination of technical skill, creativity, and attention to detail. It plays a critical role in the development of new products and technologies, and is an essential tool for designers, engineers, and architects around the world.

About Model

Marines Models

-

Ship Models are basic representation of larger ship. This models are used to keep in companies for decoration , musems and some people also kept model at home for decoration. Marines model are important in the field of engineering.The companies keep the model at their office to attract the consumer to showcase the work of ship. Jagtap miniature provide various services like cruise ship model,craft boat model, transportation ship,oil ship , piping ship etc.

About Model

Piping Models

-

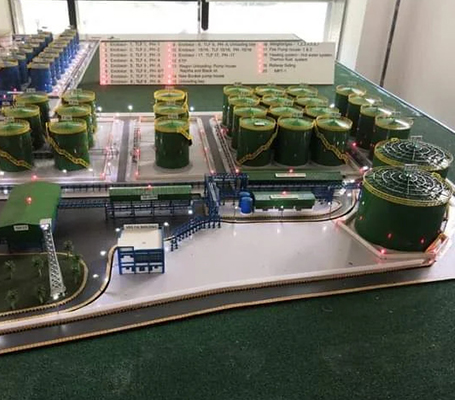

Piping model making is a specialized field of industrial model making that focuses on the creation of physical models of piping systems. These models are used for a variety of purposes, including design, testing, and education.

-

Piping models are used in a variety of industries, including oil and gas, chemical processing, and power generation. They are used to test the functionality of piping systems, evaluate the impact of different design choices, and identify potential problem areas.

-

In addition to their practical applications, piping models are also used for educational purposes. They can be used to teach students about the principles of fluid dynamics, thermodynamics, and other engineering concepts. They can also be used to demonstrate the operation of different types of valves, pumps, and other components.

-

Piping model making requires a high degree of technical skill and attention to detail. Model makers must be able to accurately reproduce the design of the piping system, while also ensuring that the model is structurally sound and functional. They must also be familiar with a variety of manufacturing techniques, including 3D printing, CNC machining, and traditional hand-crafting.

About Model

Product Model

-

At JAGTAP MINIATURE-3d Scale Model Making Company, we specialize in creating 3D models of products for marketing, advertising, and product design purposes. Our models are highly detailed and lifelike, and are designed to capture the exact look and feel of the product. We strive to provide our clients with models that are both visually stunning and accurate to the original product. With over two decades of experience in the 3D modeling industry, trust us to bring your product to life in miniature form. We specialize in variety of services, from prototyping to full-scale production, and we strive to ensure that each project is carefully crafted with the highest level of quality and detail. With years of experience in 3d modelling and a wealth of knowledge, our team will bring your vision to life!

About Model

Offshore Models

-

Offshore 3D modeling is the process of creating a digital representation of offshore structures, such as oil rigs, pipelines, and other subsea infrastructure, using specialized software tools. It involves the use of advanced 3D modeling techniques to create accurate and detailed virtual models of the offshore structures, which can be used for a variety of purposes, including design, simulations analysis, and visualization.

-

The offshore 3D modeling process typically begins with the collection of data from various sources, including surveys, engineering drawings, and other technical specifications. This data is then used to create a digital model of the offshore structure, which may include detailed geometry, materials, and other physical properties.

-

Once the 3D model is created, it can be used for a variety of purposes, including evaluating the structural integrity of the offshore structure, assessing the impact of environmental factors such as waves and currents, and optimizing the design of new offshore structures.

-

Overall, offshore 3D modeling is an essential tool for the offshore industry, allowing engineers and designers to create accurate and detailed virtual models of offshore structures, which can help to improve safety, increase efficiency, and reduce costs.